Rules of Flow

Applied Training

Improve Any KPI in Your Operation With Our On-Site Training Program.

Learn Practical Process Flow Improvement Concepts

•

Apply Concepts Directly to High Priority Business Challenges

•

Build Routines That Last Well Beyond the Training

•

Learn Practical Process Flow Improvement Concepts • Apply Concepts Directly to High Priority Business Challenges • Build Routines That Last Well Beyond the Training •

Expected Measurable Results

40% Faster Process Time

30+ Improvements Completed

200+ sq.ft. Freed

What Participants Say

What Is Covered

-

Before the program begins, we collaborate with the business leaders to define a project aligned with business needs and success metrics. We then tailor the training content and activities to the team's goals.

-

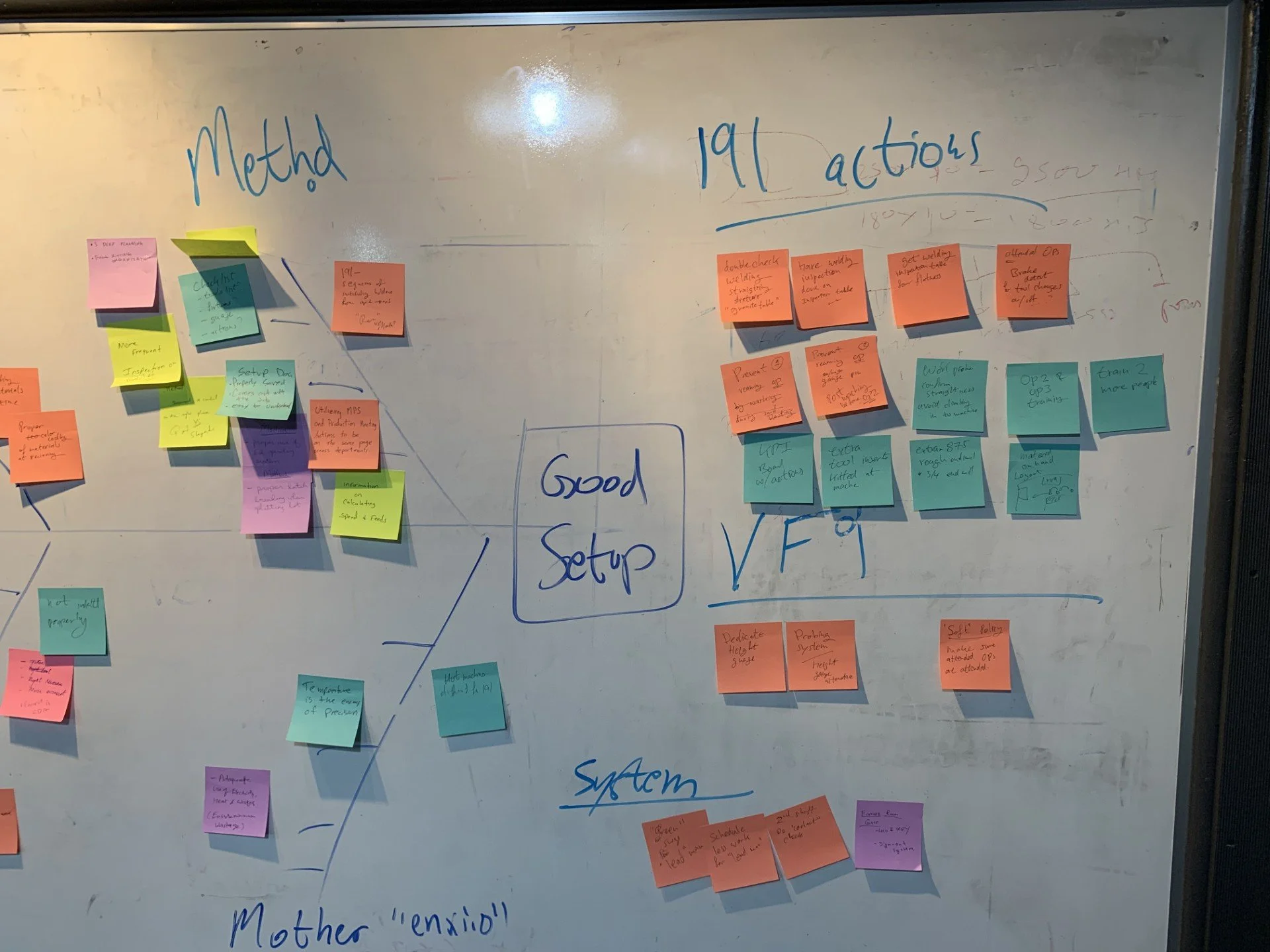

Lean Manufacturing

5S & Visual Controls

Theory of Constraints

8020 prioritization

Apply to chartered project

-

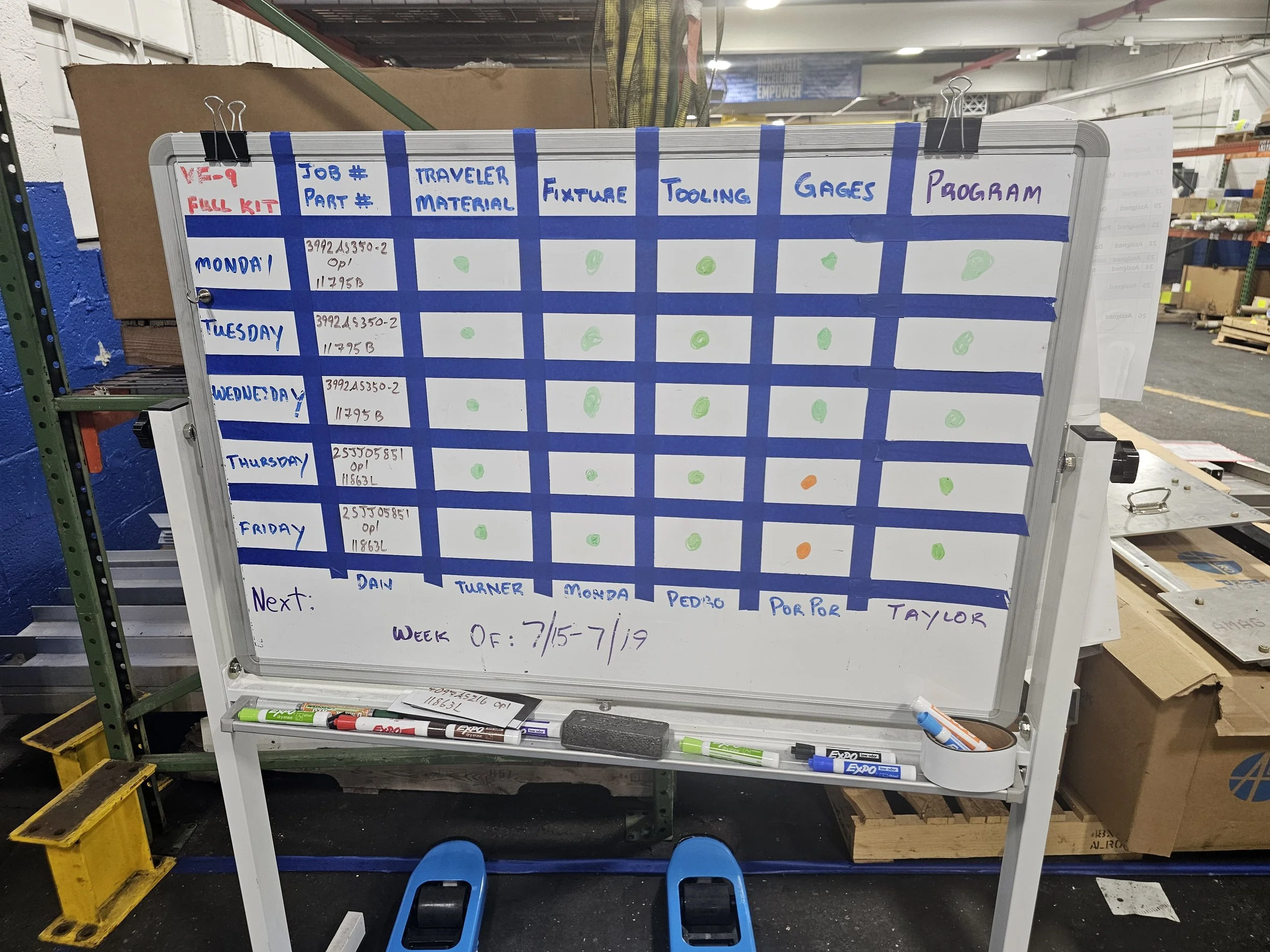

KPI visibility

Practice accountability

Data-driven problem solving

Root Cause Corrective Action

Standardization

Sample Schedule

Time Commitment:

1 Day a Week, 6 Hour Day (eg. 9:30am-3:30pm), 8 Weeks, Skipping holiday Weeks.

Why Learn From Onsite Lean Works?

On-Site and On-Demand Process Improvement Services

Trusted by Pharma, Aerospace, Aviation and Private-equity

15+ Years Expertise & Lean Six Sigma Leader, Black Belt

Who Exactly Should Attend?

Operations Team Members:

Operators, Leads, Supervisors, Manager Head of Operations.

Included Support Functions:

Planning, Quality, Engineering, Shipping & Receiving, Sales, Finance...

Maximum of 14 Team Members