Industrial Spaces Designed for Operational Performance

Tailor-made solutions by On-Site Lean Design Experts with 4-Week Design & Delivery to the Northeast US

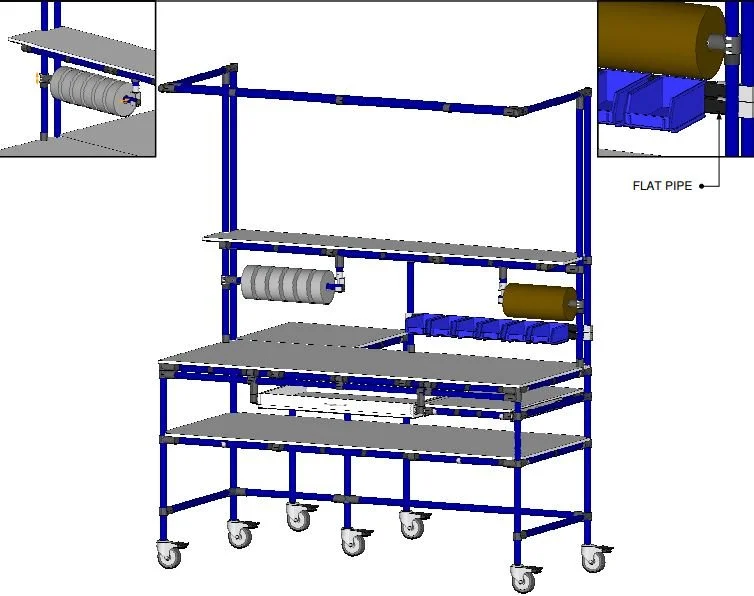

Lean Work Benches

•

Material Move Carts

•

Ergonomic Tools

•

Lean Work Benches • Material Move Carts • Ergonomic Tools •

Expertise trusted by Fortune 500 companies

On-Site and On-Demand Process Improvement Services

Trusted by Pharma, Aerospace, Aviation and Private-equity

15+ Years Expertise & Lean Six Sigma Leader, Black Belt

Expected Measurable Results

Faster Cycle Times

Faster Product Flow

Ship More Daily

Faster Inventory Turnover

30+ Fewer Defects

Avoid Defects

Increase First Pass Yield

Increase Capacity

Healthier Ergonomics

Fewer Repetitive Strains

Healthier Backs and Wrists

Safety First Culture

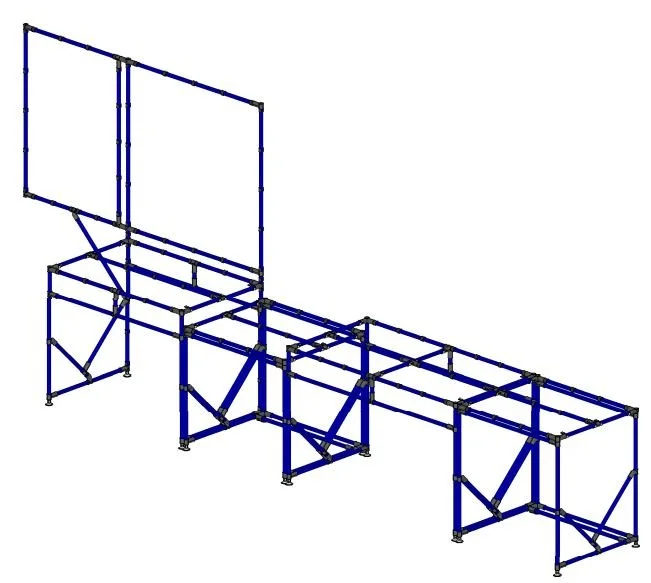

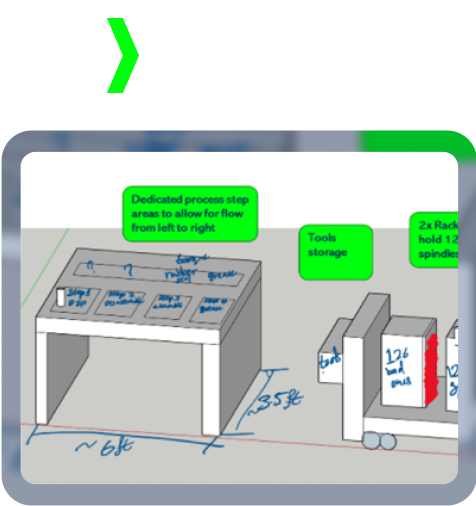

Visualizing Innovation in 3D

Our Fabricated Solutions

Human-Centered Design

Our inclusive design appraoch is focued on achieving both management objectives and improving the human factors for your operators. During onsite visits, our process engineers are observing the process and collaborating with your operators to understand their needs, wants and preferences. This human first approach enables your team to contribute to the design process and be part of the change.

-

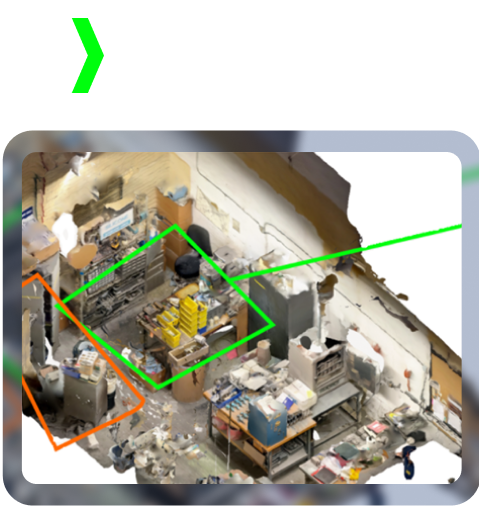

Our process engineer visits your operation to understand your objective and learns the process thru observation and operator engagement. While Onsite, a 3D scan will be completed to capture measurements critical to final design.

-

Concept is drafted for your initial approval and guidance.

Detailed engineered design is completed to ensure that all features are incorporated and loads are safely secured.

Prototype is fabricated and delivered to ensure you and your team happy and enable feedback and guidance for remaining builds.

Some customers repeat this design & prototype stage to enable engagement from their team.

-

The final design is reached as we incorporate feedback and guidance from your operating team. Whether you want 5 more or 100 more, building and delivering more carts is very scalable. We will provide you with a schedule for when carts will be delivered to facilitate a seamless switchover for your team with minimum downtime.

Your Partner to Accelerate Improvement Efforts

Process improvement takes focus on the right ideas and work to make changes. This gets exponentially tougher while the operation runs at full speed and the best team players have a full plate. We do the heavy lifting of implementing the changes so you can focus on the right ideas.

-

I visit your site to take the measurements, understand your processes and define success for the project. First, this helps me design a solution that solves your actual problem. Second, during delivery I check it actually improved operations. Most importantly, it saves you and your team the time of finding, coordinating, designing, procuring and assembling a complete solution.

-

Nothing beats the scalable benefits of getting a little better at a task that is repeated very frequently, it adds up quickly. I have helped many operations in multiple industries operate faster, more efficiently and with happier team member. I will develop a solution just for you needs that takes advantage of all the success and lessons learnt.

-

We have searched and found procured the inventory of the most commonly needed components to build up custom solutions, as well as established suppliers agreements that support our promise for quick delivery.

FAQs

-

We take away the effort of taking measurements and collaborate with your operator to learn about the issues and suggest ideas that solve the problem. Based out of New Jersey makes it easy for our Lean expert to visit your operation and design a solution specifically for your process. Onsite delivery gives your operator an opportunity to test the solution and us to rework the solution.

-

It is straightforward to search a catalog and buy a standard workbench, material cart or tool. However, whatever you end up selecting will likely solve one problem while creating a few others. Our custom solutions will focus on solving most of your process challenges.

For example, a workbench can be purchased from a retailer McMaster-Carr, and comes in standard sizes and heights. This solves your need for a workbench, but your product still sits on an unstable surface and has poor ergonomic working height for the operator. Eventually, requiring someone to fabricate a custom jig and adding a step stool for your operator.

-

Custom workflow solutions start at $3,000 with 25 sq. ft. minimum project size.

-

Yes, the first table for each project helps figure out what works and what doesn’t. After a client is happy with a design, we can fabricate many more with pricing to match the volume.

-

Major credit cards and ACH payment are accepted. Payment is expected shortly after delivery.