Showcase: CNC-shop speeds up their setups times

Consolidated Footprint, Eliminated Tool Searches, and Reduced Back Strain

After: Oversized custom workbench to match working height for HAAS VF9 machine, everything has a place, Integrated loading crane w/magnetic lifter.

Background & TLDR

Recently, we visited a local CNC shop that is focused on speeding up setup times. We launched a project with to help the team streamline their pre-setup activities thru a LEAN training program. The operations teams had to tackle a few systematic issues with their coordination efforts tooling, materials, fixtures and engineering. However, walking by the machines, it was clear the area around the machine kind of grew messy over time. During the initial visit we observed the process and took a 3D scan to aide with the lean design process. The final solution resulted we designed & built worked great to simplify the presentation of all the operators needs as well as address low-hanging ergonomic issues.

A Lean workstation would only succeed in faster setup times if the team and management applied lean manufacturing concepts in all steps leading up schedule changeover. Fortunately, this team was learning about lean manufacturing thru our Rules of Flow training and improving their supply chain and scheduling processes before plowing ahead with this custom workbench. Overall, their setups times went from over 1.5 hrs weekly average to less 1 hour, mostly due the improved coordination. This custom workbench helped sustain these gains as it reduced variation for “searching” during changeovers.

Benefits Realized

Faster setup for the next job with everything clearly

Consolidated and streamline footprint usage for WIP materials, workbenches and adjacent walkway

Mitigated ergonomic lifting hazards and reduced motions

Starting condition

The shop had an elevated working platform so simplify access. However, everything the operator needed was either on the floor, in a low workbench, in far toolbox, or more likely, has to go looking for it at different machine.

Observations during initial walk:

Operator walks away often looking for tooling, hand tools and other odds/ends

Generic toolbox was cluttered and required bending down when searching

Heaviest items (eg. 70 lb KURT Vise) was placed on floor for safety and crane underutilized for lifting

WIP and complete material was placed in walkway

Delivered Solution

We collaborated with the shop lead and operations leader thru an iterative design process. The final design brought everything together for the operator in a streamlined presentation with minimal friction. A few highlights:

Elevated ergonomic height to match elevated operator platform

heavy duty 250lb drawer slides used to hold 4x 70lb Kurt Vises at ergo height

A place for everything: 20x CAT40 integrated into shelf

Hand tool shadowboard and engineering drawing holder at eye-level

Order paperwork holders aisle side for easy check-ins with extended team

Tool tightening vise mountable on reinforced worksurface

Bonus: Magnetic lift and extend sliding rail to eliminate lifting hazards into machine envelope

Space opportunities made possible.

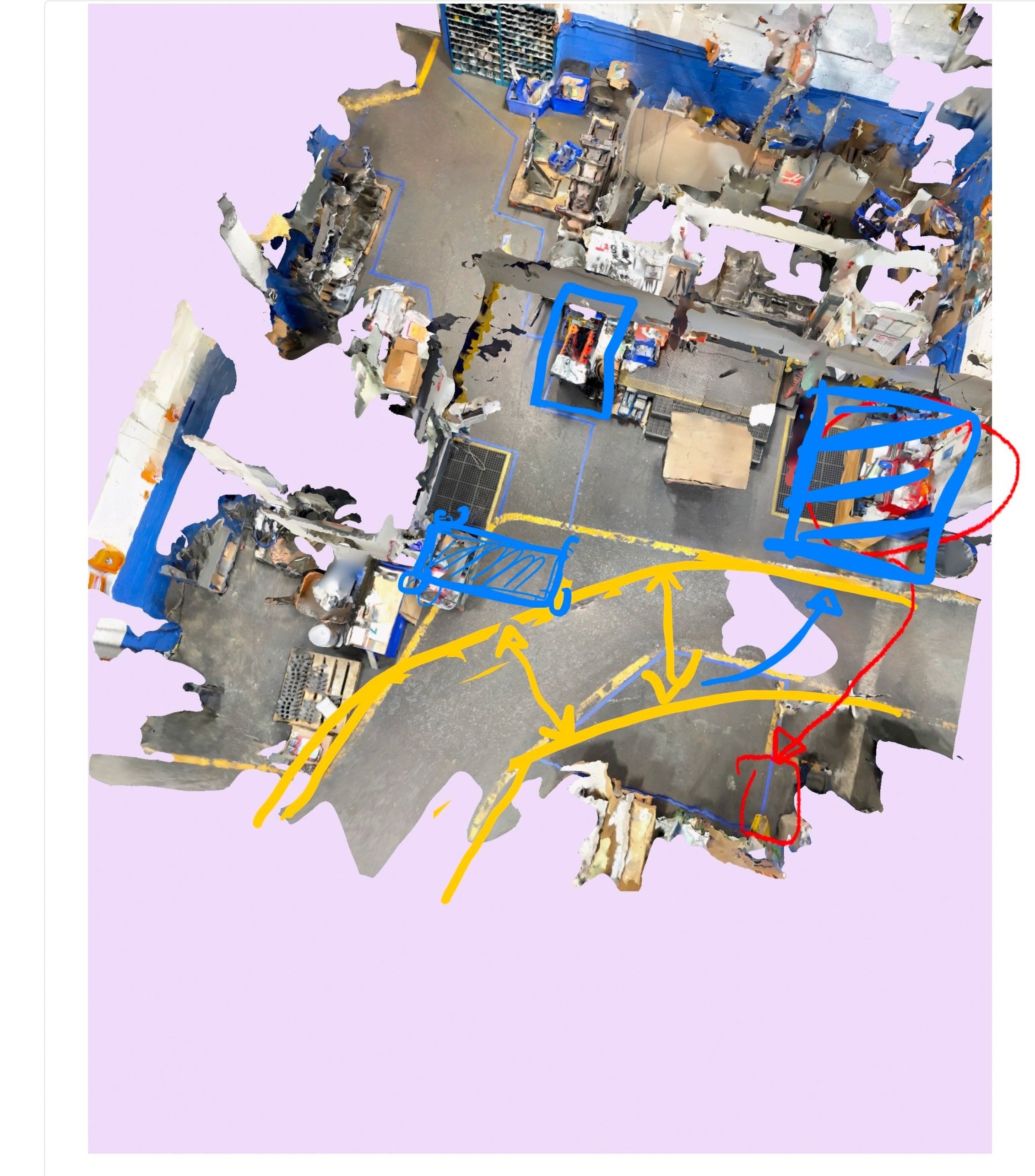

3D scanning the space gave the design team a bird's-eye view of the space and opened up opportunities to maximize the space for the flow of people and products.

For example, by consolidating the footprint and taking advantage of the vertical, a few opportunities opened up:

Clear away old workbenches/toolboxes

Move WIP and Complete material closer to the machine and within the crane lifting envelope

Shift the walkway to avoid slowdown turns

More space for the nearby machine to position a setup workbench ideally for the operator